Alloy 20 Instrumentation Ball Valves

Inconel® alloy 20 2 Way Ball Valves Manufacturer, Suppliers of Alloy 20 High Pressure Ball Valve, Alloy 20 One-Piece Instrumentation Ball Valves, Carpenter 20 3 Piece Ball Valves, Alloy 20 Instrumentation Ball Valves At Factory Price In India.

Vintex Steel & Engg. Co. is a standard manufacturer and supplier of Alloy 20 Instrumentation Ball Valves, which are difficult in nature and feature good sized programs.

It is regularly utilized in chemical processing and marine system in addition to quite a few airframe components. It has appropriate tensile residences at ambient temperatures as compared by means of different titanium. It is regularly utilized in bellows, plane structural, honeycomb, gaskets, plane skin, and warmth exchanger parts. They are long lasting in nature and feature extensive programs. It has first-rate tensile traits at ambient temperatures associated via different titanium. Alloy 20 Instrumentation Valves are designed to perfectly suit the exact demand of various critical application desires. Alloy 20 Instrumentation High Pressure Ball Valves is time and again used at cryogenic temperatures, by means of having low magnetic permeability and good roughness.

Inconel® alloy 20 Flanged Ball Valves, Carpenter 20 Multiport Ball Valve, Carpenter 20 Rising Stem Ball Valve Stockist, UNS N08020 Instrumentation Ball Valve, Alloy 20 2 Piece Ball Valves, UNS N08020 Four Way Ball Valves, Nickel Alloy 20 Lined Ball Valves, DIN 2.4660 4 Way Ball Valve Supplier, Alloy 20 Trunnion Ball Valves, Alloy 20 Ball Valve Manufacturer In India.

Table of Content

- Material Specification Chart Of Alloy 20 Ball Valves

- Alloy 20 Ball Valves Equivalent Grade

- Most Commonly used Alloy 20 Ball Valves Types

- Dimensions Of Alloy 20 Instrumentation Ball Valves

- Stock List Of Alloy 20 Instrumentation Ball Valves

- Chemical Composition of Alloy 20 Instrumentation Ball Valves

- Mechanical Properties of Alloy 20 Ball Valve

- Alloy 20 Ball Valves Uses and Application

- Alloy 20 Instrumentation Ball Valves Export Countries

Alloy 20 instrument ball valves are designed and fabricated to perfectly suit all the demands of critical applications. We are reliable and trustworthy industry that is customer focused is focusing on easily fulfilling all the demands of every esteem buyers. It is normally utilized in marine system and chemical processing, together in company of quite a number airframe parts. It has high-quality resistance to corrosion in maximum normal and a number of commercial procedure atmospheres. Resistance to crack and fatigue propagation is super in such Alloy 20Cb3 Instrumentation Ball Valves, which holds appropriate strength, ductility, formability and weld ability. It is especially utilized in turbine and airframe engine components, and additionally in surgical implants. It is the maximum significantly used grade and so is age hard enable via way of warmth behavior for to acquire even advanced strengths.

Material Specification Chart Of Alloy 20 Ball Valves

| Size | 1/8″ To 2″ / 6 Mm To 50 Mm |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way, 4 Way, 5 Way |

| Pressure Rating | 1500 Psi, 3000 Psi, 6000 Psi, 10000 Psi, 15000 Psi, 20000 Psi |

| Seal Ring Material | PTFE, PVDF, DELRIN, PEEK, GRAPHITE |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design Standards | Valve Body – ASME B 16.34 Valve Flanges – ASME 16.5 Face to Face – ASME B 16.10 (long pattern) |

| End Connection | Flanged End / Screwed End / Butt Weld End / Screwed to BSPT / NPT / Socket Weld / Buttweld with extended Nipple |

| Ball Valve Type | One Piece, Two Piece, Three Piece, 3 Way, 4 Way, High temperature, fire safe, trunnion mounted Full Bore, Metal Seated, separate ball and shaft, split body design, pneumatically operated ball valve with Manual Over ride and gas purging provision. |

| Media Temperature | (-120* C To 500*C )Range As Per Pressure |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

| Application | Material Handling Equipment, Earth Moving Machineries , Power Generating Plant , Steel Manufacturing Plant , Mining Industries , Chemical Processing Machines , Piping Line , Paint Industries , Trucks And Trailers , Automation , Agriculture Machines , Aerospace & Defence Equipments |

Alloy 20 Ball Valves Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | EN |

| Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo |

Most Commonly used Alloy 20 Ball Valves Types

Alloy 20 2 Way Ball Valve

Alloy 20 3 Way Ball Valve

Alloy 20 4 Way Ball Valve

Alloy 20 5 Way Ball Valve

Alloy 20 Panel Mounted Ball Valve

Alloy 20 Butterfly Handle Ball Valve

Alloy 20 Short Handle Ball Valve

Alloy 20 Round Body Ball Valve

Alloy 20 Square Body Ball Valve

Alloy 20 Full Bore Ball Valve

Alloy 20 Reduced Bore Ball Valve

Alloy 20 Compression Ball Valve

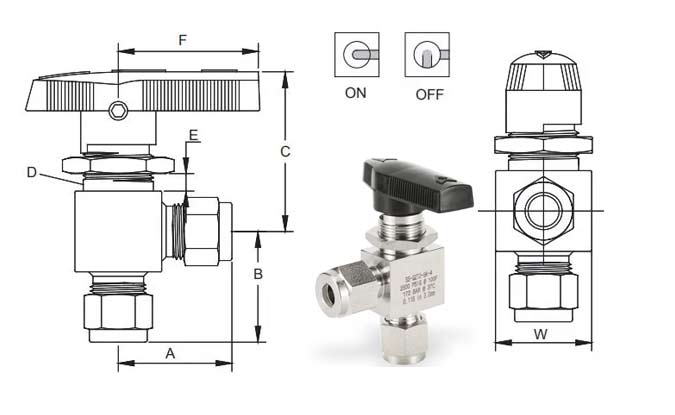

Dimensions Of Alloy 20 Instrumentation Ball Valves

| END CONNECTION SIZE | ORIFICE | A | |||

|---|---|---|---|---|---|

| (IN) | (MM) | (IN) | (MM) | (IN) | (MM) |

| 1/8 | 3.17 | 0.09 | 2.4 | 1.01 | 25.5 |

| 3/16 | 4.76 | 0.13 | 3.2 | 1.1 | 28 |

| 1/4 | 6.35 | 0.19 | 4.8 | 1.2 | 30 |

| 3/8 | 9.52 | 0.28 | 7.1 | 1.45 | 36.5 |

| 1/2 | 12.7 | 0.41 | 10.3 | 1.74 | 44.2 |

| 0.12 | 3 | 0.09 | 2.4 | 1.01 | 25.5 |

| 0.24 | 6 | 0.19 | 4.8 | 1.2 | 30 |

| 0.31 | 8 | 0.19 | 4.8 | 1.23 | 31.2 |

| 0.39 | 10 | 0.28 | 7.1 | 1.45 | 36.5 |

| 0.47 | 12 | 0.41 | 10.3 | 1.74 | 44.2 |

| B | C | D | |||

|---|---|---|---|---|---|

| (IN) | (MM) | (IN) | (MM) | (IN) | (MM) |

| 1.01 | 25.5 | 1.36 | 34.5 | 0.59 | 15.1 |

| 1.1 | 28 | 1.36 | 34.5 | 0.59 | 15.1 |

| 1.2 | 30 | 1.47 | 37.3 | 0.78 | 19.8 |

| 1.45 | 36.5 | 2.07 | 52.5 | 1.13 | 28.7 |

| 1.74 | 44.2 | 2.44 | 62 | 1.5 | 38.1 |

| 1.01 | 25.5 | 1.36 | 34.5 | 0.59 | 15.1 |

| 1.2 | 30 | 1.47 | 37.3 | 0.59 | 15.1 |

| 1.23 | 31.2 | 1.47 | 37.3 | 0.78 | 19.8 |

| 1.45 | 36.5 | 2.07 | 52.5 | 1.13 | 28.7 |

| 1.74 | 44.2 | 2.44 | 62 | 1.5 | 38.1 |

| E | W | F | CV | |||

|---|---|---|---|---|---|---|

| (IN) | (MM) | (IN) | (MM) | (IN) | (MM) | |

| 1/4 | 6.4 | 1.26 | 32 | 0.58 | 14.7 | 0.15 |

| 1/4 | 6.4 | 1.26 | 32 | 0.58 | 14.7 | 0.35 |

| 1/4 | 6.4 | 1.26 | 32 | 0.78 | 19.8 | 0.9 |

| 3/8 | 9.7 | 1.5 | 38.1 | 1.12 | 28.5 | 2 |

| 3/8 | 9.7 | 2.36 | 60 | 1.5 | 38 | 4.6 |

| 1/4 | 6.4 | 1.26 | 32 | 0.58 | 14.7 | 0.15 |

| 1/4 | 6.4 | 1.26 | 32 | 0.78 | 19.8 | 0.9 |

| 1/4 | 9.7 | 1.5 | 38.1 | 0.78 | 19.8 | 0.9 |

| 3/8 | 9.7 | 1.7 | 43 | 1.12 | 28.5 | 2 |

| 3/8 | 9.7 | 2.36 | 60 | 1.5 | 38 | 4.6 |

We are One Of The Most Trusted Supplier Of Alloy 20 Instrumentation Ball Valves in India. For final Alloy 20 Instrumentation Ball Valve Price List. Please Call on +91 22 6636 2645 or drop an E-Mail : sales@vintexsteel.com

Other Related Products

- Inconel 600 Instrumentation Ball Valves

- Inconel 601 Instrumentation Ball Valves

- Inconel 625 Instrumentation Ball Valves

- Incoloy 800 Instrumentation Ball Valves

- Incoloy 825 Instrumentation Ball Valves

- Hastelloy C22 Instrumentation Ball Valves

- Hastelloy C276 Instrumentation Ball Valves

- Monel 400 Instrumentation Ball Valves

- Nickel Alloy 200 / 201 Instrumentation Ball Valves

- Titanium Gr 2 Instrumentation Ball Valves

- Titanium Gr 5 Instrumentation Ball Valves

- Alloy 20 Instrumentation Ball Valves

Test Certificates Of Alloy 20 Ball Valves

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Alloy 20 Instrumentation Ball Valves

- Alloy 20 One-Piece Ball Valves

- Nickel Alloy 20 Instrumentation Ball Valves

- Alloy 20Cb-3® Three Piece Ball Valve

- Carpenter 20 Hydraulic Ball Valves

- Alloy 20 Swagelok Ball Valves Stockist

- Alloy 20 Instrument Ball Valve

- Carpenter 20 Panel Mount Ball Valves

- Alloy 20 High Pressure Instrument Ball Valve

- Carpenter 20 High Pressure Ball Valves

- Alloy 20 Instrumentation Ball Valves

- Inconel® alloy 20 Floating Ball Valves

- UNS N08020 2 Piece Ball Valves

- Alloy 20 Single-piece Ball Valve

- Alloy 20 Forged Ball Valve

- Alloy 20 1 Piece Ball Valves Exporter

- DIN 2.4660 3 Piece Ball Valves

- Inconel® alloy 20 Three Way Ball Valve Supplier

- DIN 2.4660 Multiport Ball Valves

- Inconel® alloy 20 Five-Way Ball Valves

- Alloy 20 Sanitary Ball Valves Distributor

- Alloy 20 4 Way Ball Valve

- UNS N08020 Rising Stem Ball Valve

- Alloy 20 2-Piece Instrumentation Ball Valve

- Alloy 20 Three Piece High Pressure Ball Valve

- Alloy 20 Three Piece Compression Ended Ball Valve

- Nickel Alloy 20 4 Way Ball Valves Manufacturer

- Alloy 20Cb-3® Three Piece Bolted Ball Valve

- Alloy 20Cb-3® Lined Ball Valve

- Carpenter 20 Three Piece Firesafe Ball Valve

- Inconel® alloy 20 High Pressure 2 Way Ball Valve

- Alloy 20 Industrial Ball Valves Price

- Alloy 20Cb-3® 3 Pc Ball Valve Dealer

- UNS N08020 Socket Weld End Ball Valve

- Carpenter 20 Trunnion Ball Valves

Chemical Composition of Alloy 20 Instrumentation Ball Valves

| Grade | Ni | C | Mn | P | S | Si | Cr | Nb | Mo | Cu |

| Alloy 20 | 32 – 38 | 0.02 max | 1 – 2 | 0.02 max | 0.005 max | 0.7 max | 19 – 21 | 0.1 – 0.3 | 2 – 3 | 3 – 4 |

Mechanical Properties of Alloy 20 Ball Valve

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi – 35,000, MPa – 241 | 30 % |

Alloy 20 Ball Valves Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment

Previous

Next

Alloy 20 Instrumentation Ball Valves Export Countries

Kazakhstan, Egypt, Sri Lanka, Singapore, Israel, Canada, Mexico, Saudi Arabia, Pakistan, Mexico, Poland, Lebanon, Oman, Croatia, India, Portugal, Thailand, Sweden, Australia, United Arab Emirates, Italy, Kenya, Norway, Afghanistan, Yemen, South Korea, Argentina, Netherlands, Bolivia, Switzerland, Qatar, Greece, New Zealand, Turkey, Slovakia, Morocco, Ghana, Chile, Belgium, Jordan, Iraq, Azerbaijan, Denmark, Indonesia, Hong Kong, Chile, Ukraine, China, United States, Spain, Iran, Japan, Hungary, Nigeria, Serbia, Poland, Trinidad & Tobago,Tunisia, Gabon, Bangladesh, Lithuania, Czech Republic, Mongolia, Finland, Vietnam, Estonia, Taiwan, France, Russia, Bhutan, Bahrain, Iran, Venezuela, Algeria, Bulgaria, Peru, Belarus, South Africa, Malaysia, Costa Rica, Austria, Philippines, Romania, United Kingdom, Angola, Nigeria, Libya, Ecuador, Colombia, Kuwait, Brazil.

Other Instrumentation Ball Valves

Instrumentation Ball Valves

Product Categories

Have Any Questions ?

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.

Contact Us

Buy Alloy 20 Ball Valves and Alloy 20 2 Piece Ball Valve At Factory Price In India

Contact Now